Membrane Switches

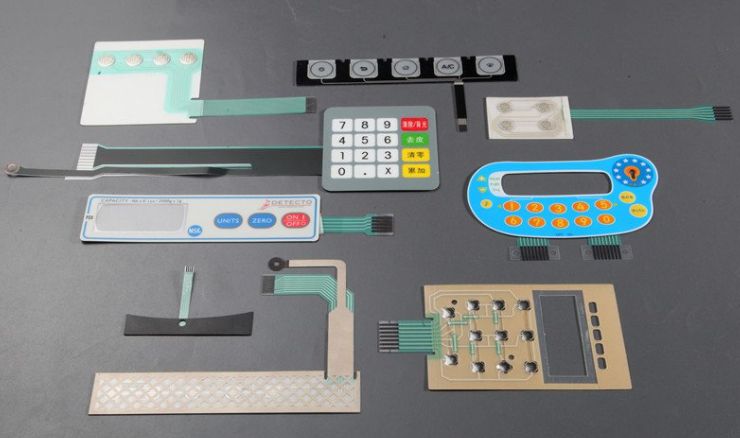

Membrane Keypads & Keyboards

Industrial Labels

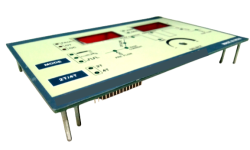

Membrane Switches Graphic Overlays

Custom Complex Designs for Membrane Switches

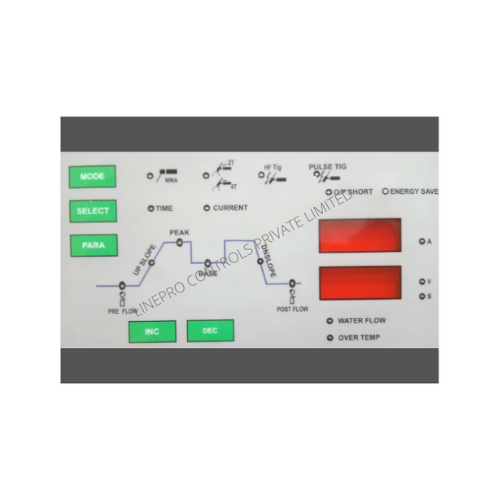

Why Linepro's Membrane Switches

Over 30 years, we have served custom membrane switches to wide range of industry verticals ranging from automobile to medical industry and waste recycling and disposal to dairy industry. We are leaders in Membrane Switch manufacturing and offer application specific switches. If the application priority is hygiene, or the membrane switch is exposed to harsh working environments, we offer the most suitable switches for every industry.

Linepro’s Membrane switches are induced with various features to meet the expectations of application. Profile, domes and backlight illumination enhance the effectiveness of the membrane switch to give that impressively sophisticated and technologically advanced eye-catchy look. The size, design and color can be customized as desired. Membrane switches are layered, this allows freedom for product designers and engineers to design and implement a very precise customer experience.

Affordability

Complete in-house manufacturing prompts low-cost membrane switches

Simplified Circuitry

Low voltage and compact circuit design in form of flexible printed circuits and rugged PCBs

Custom Design

Application specific design approach gives durable and efficient membrane switches

Linepro's Manufacturing Capabilities

When you partner with Linepro, you are selecting a world-class membrane switch manufacturer with a specific track record over 30 years. With a loyalty rate as high as 98 percent and providing long-lasting quality of our products we are the top option of a switch maker for your next project.

With cutting-edge technology we are proud when satisfied customers recognize us as the sole guarantors for membrane switches! Are you ready to begin? Get in touch with our experienced consultant team today to start your project for membrane switches.

Free Membrane Switches Design Guide

Our Team Just a Click Away!

Our No obligation and Free Consultation for your Membrane Switch Project. Share your details and we start guiding you!

Types of Membrane Switches

Linepro

Worldwide

5000+

Custom Designs

40000+

Registered Customers

160+

Client Countries

Membrane Switches - Designed, Engineered & Manufactured at our facility

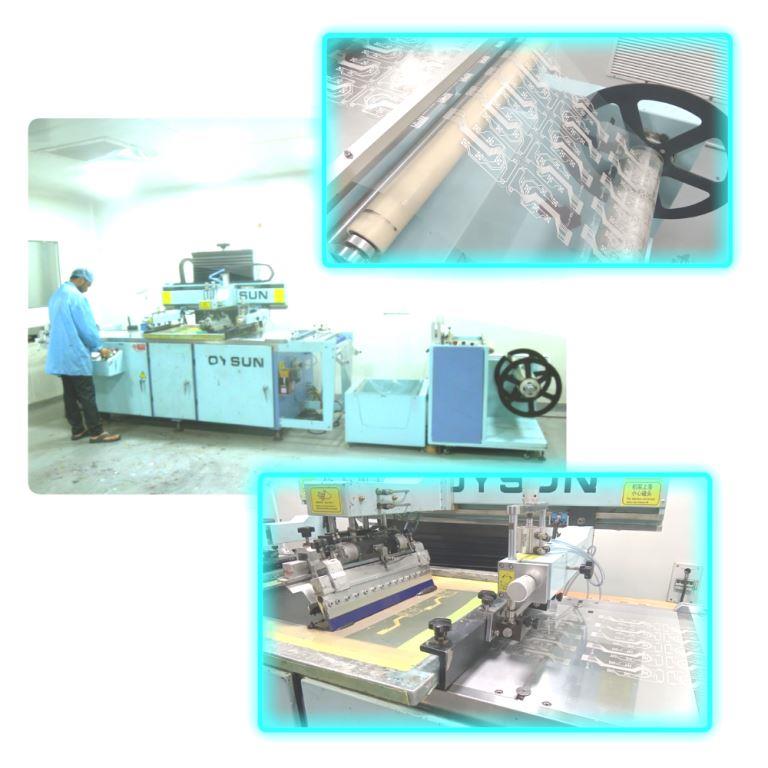

Flexible Circuits for Membrane Switches

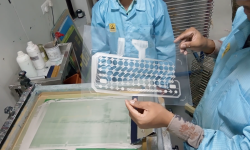

The flexible circuits of Membrane Switches are printed at Linepro’s facility using modern and highly accurate automatic roll-to-roll screen printing machines. It is an automated screen printing process where a polymer thick film (PTF) is used as a print media. Silver or copper based conductive inks are pressed through a substrate to be superimposed on the PTF media. A dielectric layer is finally applied to mask conductive traces and left open where ink traces should be present for electrical contacts.

Our in-house screen printing facility promotes scalable production of printed flexible circuits for membrane switches to meet the ever increasing demands worldwide.

Electronics Assembly

Quality Control

R&D Department

Mechanical Assembly

30 years of experience of innovating, designing and producing membrane switches

Worldwide delivery. Strong distribution network across all continents.

Competitive Pricing Guaranteed.